| Availability: | |

|---|---|

380V

1.5KW~15KW

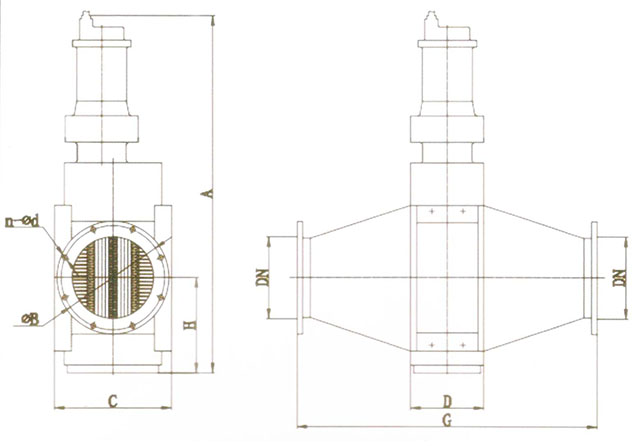

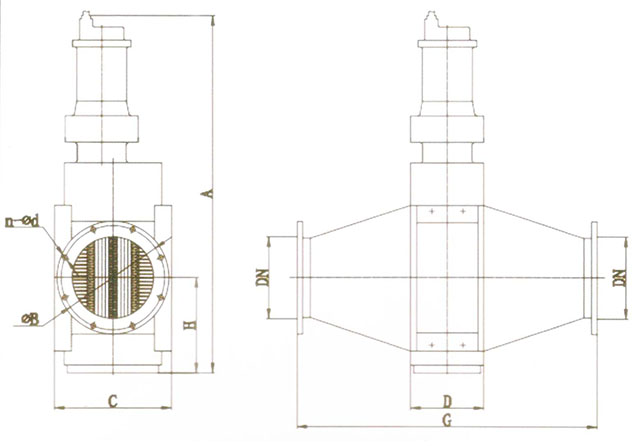

The inline channel sewage grinder is installed in the flange type of the pipeline and grinds the solid matter, suspended matter, and long and thin fibers in the pipeline conveying medium into small particles. It is mainly used in sludge digesters in sewage treatment, which reduces the amount of sludge in the sludge digestion cycle, speeds up the digestion speed, and reduces the flow time of sludge circulation.

The Pipe Pulverizer fits most existing in-line equipment or piping applications and does not require additional piping or modifications to the piping system.

The unique dual-axis design ensures that impurities of different materials are completely crushed;

According to the different water intakes, the pipe grinder has a smaller head loss, increases the circulation effect, and makes the water flow more smoothly.

It adopts a tissue sealing device formed by a mechanical seal and a skeleton oil seal, no need to flush the seal, no need to adjust the sealing packing, and it is very convenient in the process of use and maintenance

Modular design with different gear configurations to meet users' special application requirements.

Can be used in sewage lifting pumping station

The inline channel sewage grinder is installed in the flange type of the pipeline and grinds the solid matter, suspended matter, and long and thin fibers in the pipeline conveying medium into small particles. It is mainly used in sludge digesters in sewage treatment, which reduces the amount of sludge in the sludge digestion cycle, speeds up the digestion speed, and reduces the flow time of sludge circulation.

The Pipe Pulverizer fits most existing in-line equipment or piping applications and does not require additional piping or modifications to the piping system.

The unique dual-axis design ensures that impurities of different materials are completely crushed;

According to the different water intakes, the pipe grinder has a smaller head loss, increases the circulation effect, and makes the water flow more smoothly.

It adopts a tissue sealing device formed by a mechanical seal and a skeleton oil seal, no need to flush the seal, no need to adjust the sealing packing, and it is very convenient in the process of use and maintenance

Modular design with different gear configurations to meet users' special application requirements.

Can be used in sewage lifting pumping station

Model | A (mm) | B | C | DN (mm) | G | H (mm) | n-d | Flow (m³/h) | Power (kw) |

| FSG-100 | 1250 | 220 | 450 | 100 | 510 | 290 | 8-Φ18 | 80 | 2.2 |

| FSG-150 | 1300 | 285 | 450 | 150 | 650 | 320 | 8-Φ22 | 130 | 2.2 |

| FSG-200 | 1350 | 340 | 450 | 200 | 910 | 350 | 8-Φ22 | 250 | 2.2 |

| FSG-250 | 1400 | 395 | 450 | 250 | 920 | 380 | 12-Φ22 | 310 | 3.0 |

| FSG-300 | 1450 | 445 | 450 | 300 | 960 | 400 | 12-Φ22 | 360 | 3.0 |

| FSG-350 | 1500 | 550 | 450 | 350 | 960 | 430 | 16-Φ22 | 420 | 3.0 |

| FSG-400 | 1600 | 565 | 450 | 400 | 1000 | 460 | 16-Φ26 | 460 | 4.0 |

Model | A (mm) | B | C | DN (mm) | G | H (mm) | n-d | Flow (m³/h) | Power (kw) |

| FSG-100 | 1250 | 220 | 450 | 100 | 510 | 290 | 8-Φ18 | 80 | 2.2 |

| FSG-150 | 1300 | 285 | 450 | 150 | 650 | 320 | 8-Φ22 | 130 | 2.2 |

| FSG-200 | 1350 | 340 | 450 | 200 | 910 | 350 | 8-Φ22 | 250 | 2.2 |

| FSG-250 | 1400 | 395 | 450 | 250 | 920 | 380 | 12-Φ22 | 310 | 3.0 |

| FSG-300 | 1450 | 445 | 450 | 300 | 960 | 400 | 12-Φ22 | 360 | 3.0 |

| FSG-350 | 1500 | 550 | 450 | 350 | 960 | 430 | 16-Φ22 | 420 | 3.0 |

| FSG-400 | 1600 | 565 | 450 | 400 | 1000 | 460 | 16-Φ26 | 460 | 4.0 |

There are several advantages of using an inline sewage grinder (also known as a channel sewage grinder) in wastewater treatment systems, including:

Improved efficiency:

An inline sewage grinder can grind up solid waste materials, such as wipes, rags, and plastics, that might otherwise clog or damage downstream equipment, such as pumps and valves. By grinding up this material, the grinder helps to improve the overall efficiency of the wastewater treatment process.

Reduced maintenance:

By preventing clogs and damage to downstream equipment, an inline sewage grinder can reduce the need for maintenance and repairs, which can be costly and time-consuming.

Increased capacity:

An inline sewage grinder can help to increase the capacity of a wastewater treatment system by allowing it to handle more solid waste material. This can be particularly important in systems that are nearing capacity or experiencing frequent clogs.

Improved quality:

By removing solid waste materials from the wastewater stream, an inline sewage grinder can help to improve the overall quality of the treated water, making it safer for discharge into the environment.

Cost-effective:

While an inline sewage grinder may represent an initial investment, it can ultimately be a cost-effective solution to prevent downstream equipment damage, reduce maintenance costs, and increase the lifespan of the overall system.

Versatile:

Inline sewage grinders can be used in a variety of applications, including municipal wastewater treatment plants, industrial wastewater treatment facilities, and commercial buildings. They are also available in a range of sizes and configurations to suit different system requirements.

Easy to install:

Inline sewage grinders are typically easy to install and can be integrated into existing wastewater treatment systems without significant modifications. This can help to minimize downtime and disruption to operations.

Environmentally friendly:

By reducing the amount of solid waste material that enters the wastewater stream, an inline sewage grinder can help to minimize the impact of wastewater treatment systems on the environment. This can be particularly important in areas where the treated water is discharged into sensitive ecosystems or waterways.

Overall, the use of an inline sewage grinder can offer several benefits for wastewater treatment systems, including improved efficiency, reduced maintenance, increased capacity, improved quality, cost-effectiveness, versatility, ease of installation, and environmental friendliness.

There are several advantages of using an inline sewage grinder (also known as a channel sewage grinder) in wastewater treatment systems, including:

Improved efficiency:

An inline sewage grinder can grind up solid waste materials, such as wipes, rags, and plastics, that might otherwise clog or damage downstream equipment, such as pumps and valves. By grinding up this material, the grinder helps to improve the overall efficiency of the wastewater treatment process.

Reduced maintenance:

By preventing clogs and damage to downstream equipment, an inline sewage grinder can reduce the need for maintenance and repairs, which can be costly and time-consuming.

Increased capacity:

An inline sewage grinder can help to increase the capacity of a wastewater treatment system by allowing it to handle more solid waste material. This can be particularly important in systems that are nearing capacity or experiencing frequent clogs.

Improved quality:

By removing solid waste materials from the wastewater stream, an inline sewage grinder can help to improve the overall quality of the treated water, making it safer for discharge into the environment.

Cost-effective:

While an inline sewage grinder may represent an initial investment, it can ultimately be a cost-effective solution to prevent downstream equipment damage, reduce maintenance costs, and increase the lifespan of the overall system.

Versatile:

Inline sewage grinders can be used in a variety of applications, including municipal wastewater treatment plants, industrial wastewater treatment facilities, and commercial buildings. They are also available in a range of sizes and configurations to suit different system requirements.

Easy to install:

Inline sewage grinders are typically easy to install and can be integrated into existing wastewater treatment systems without significant modifications. This can help to minimize downtime and disruption to operations.

Environmentally friendly:

By reducing the amount of solid waste material that enters the wastewater stream, an inline sewage grinder can help to minimize the impact of wastewater treatment systems on the environment. This can be particularly important in areas where the treated water is discharged into sensitive ecosystems or waterways.

Overall, the use of an inline sewage grinder can offer several benefits for wastewater treatment systems, including improved efficiency, reduced maintenance, increased capacity, improved quality, cost-effectiveness, versatility, ease of installation, and environmental friendliness.